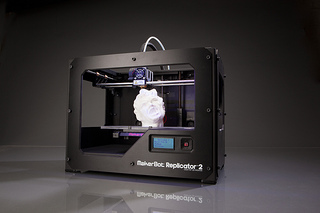

3D Printers for Everyone?

We’ve blogged before about the potential of 3D food printers, but at the moment such printers seem out of reach for the average consumer. Perhaps not for long — a new paper by B.T. Wittbrodt, A.G. Glover, J. Laureto, G.C. Anzalone, D. Oppliger, J.L. Irwin, and J.M. Pearce conducts a cost-benefit analysis of 3D printers for the average household:

This study reports on the life-cycle economic analysis (LCEA) of RepRap technology for an average U.S. household. A new low-cost RepRap is described and the costs of materials and time to construct it are quantified. The economic costs of a selection of twenty open-source printable designs (representing less than 0.04% of those available), are typical of products that a household might purchase, are quantified for print time, energy, and filament consumption and compared to low and high Internet market prices for similar products without shipping costs. The results show that even making the extremely conservative assumption that the household would only use the printer to make the selected twenty products a year the avoided purchase cost savings would range from about $300 to $2,000/year. Assuming the 25 hours of necessary printing for the selected products is evenly distributed throughout the year these savings provide a simple payback time for the RepRap in 4 months to 2 years and provide an ROI between>200% and >40%. As both upgrades and the components that are most likely to wear out in the RepRap can be printed and thus the lifetime of the distributing manufacturing can be substantially increased the unavoidable conclusion from this study is that the RepRap is an economically attractive investment for the average U.S. household already. It appears clear that as RepRaps improve in reliability, continue to decline in cost and both the number and assumed utility of open-source designs continues growing exponentially, open-source 3-D printers will become a mass-market mechatronic device.

(HT: Marginal Revolution)

Comments